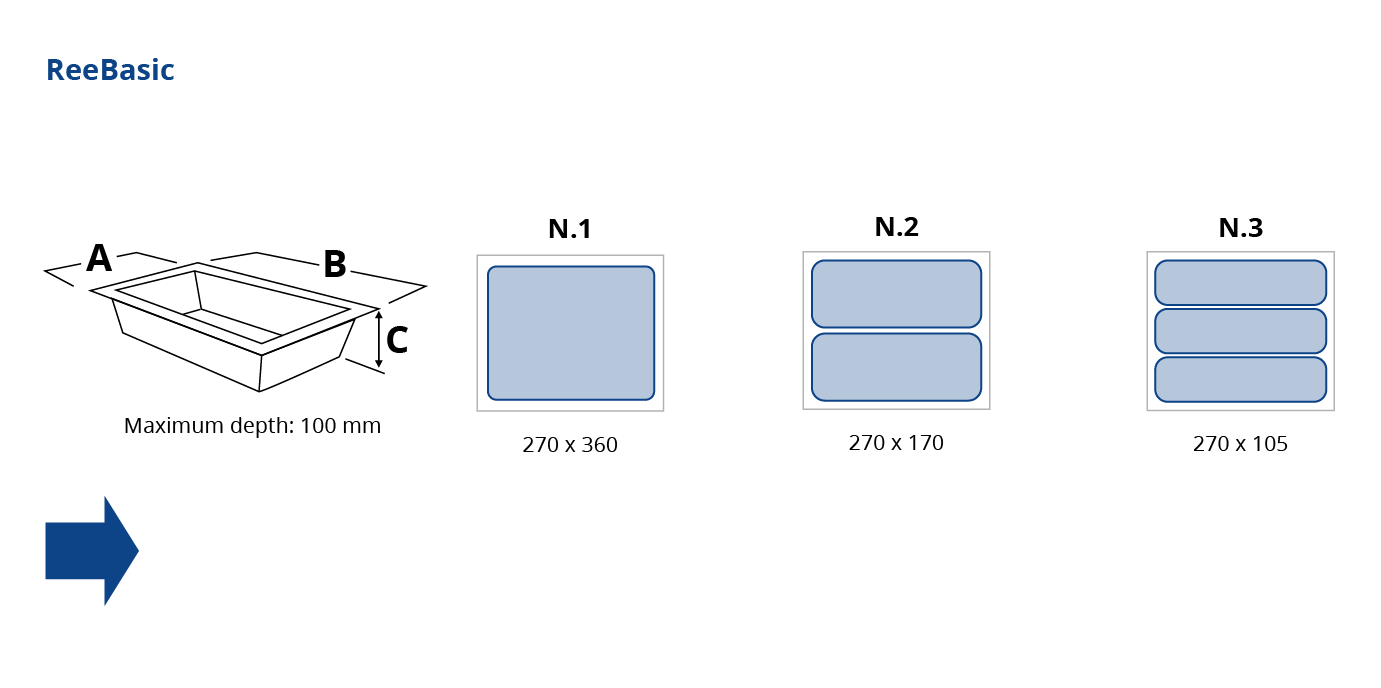

ReeBasic VG

A very compact fully automatic MAP capable tray sealer machine for all kinds of pre-formed trays. An all stainless steel frame and high reliability make the ReeBasic an ideal model for small and medium productions. Standard vacuum pump is 40m3/h. The ReeBasic does not require any pressurized air supply so considerable savings in energy and general maintenance provide a good return on investment. Being so compact in size this machine is readily placed anywhere needed.

Die-Set Compatibility with ReeSeal 32 SX and ReeTray 20.

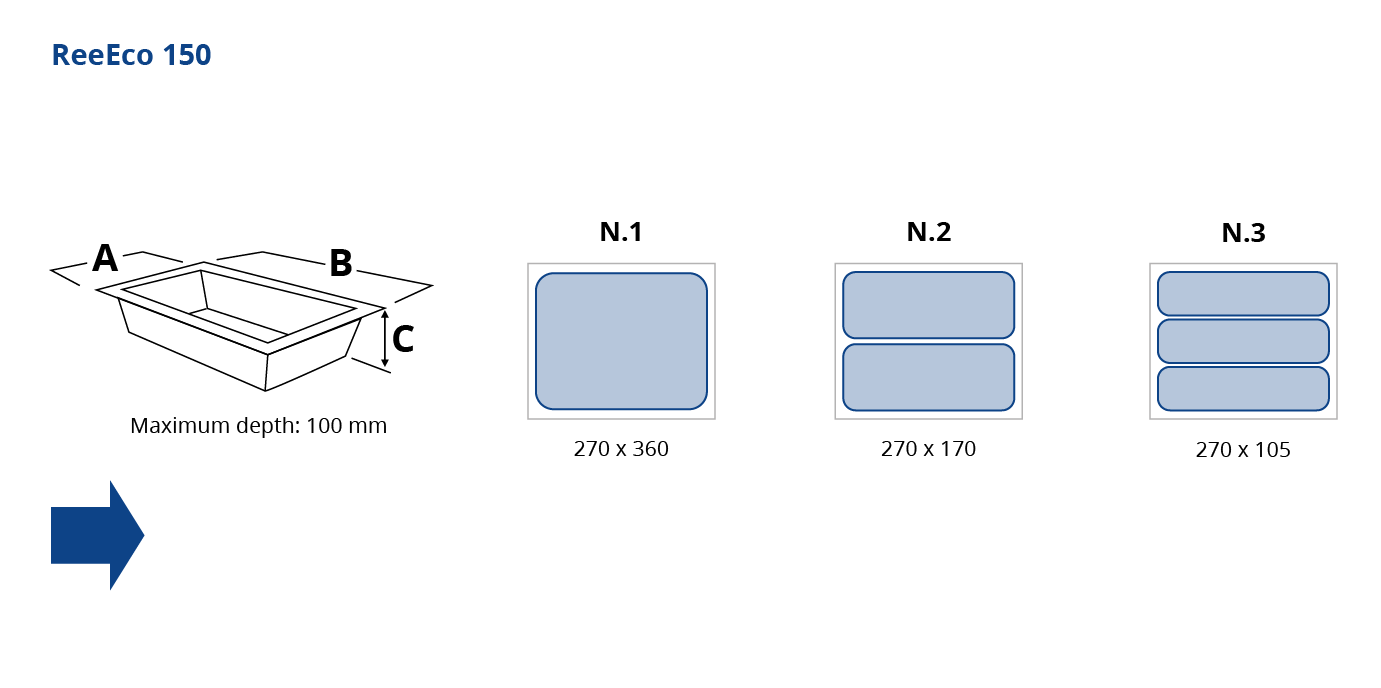

ReeEco 20

High performance, less power consumption, and compact overall dimensions make this automatic tray sealer the most innovative and rewarding machine among Reepack’s latest developments. With a user friendly control panel, standard in feed conveyor with up to 3 loading positions, an automatic belt conveyor for tray discharge, give this model a sophisticated level of operation. The Reeco 150 has a standard vacuum pump, 60m3/h, allowing high vacuum settings and high performance. This machine does not require any pressurized air supply so considerable savings in energy provide a good return on investment.

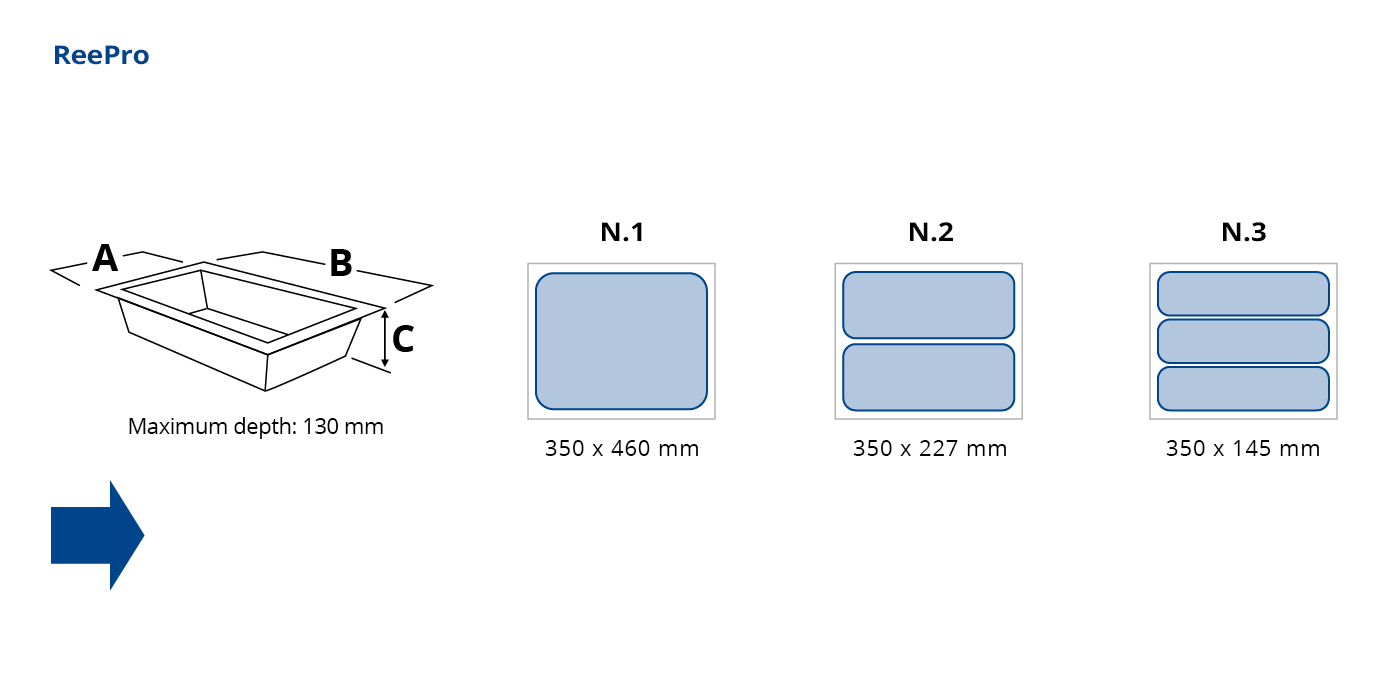

ReePro

Automatic tray sealer SINGLE DIE-SET suitable for both artisanal and industrial productions.

Ideal for vacuum skin packaging applications, the ReePro features a built-in pre-heating station, active film tensioning device, and a special rapid-vacuum system. This machine is suitable for packaging fresh or frozen food, and ready-meals in trays; for ambient sealing, modified atmosphere (MAP), or vacuum skin (VSP) applications.

Single or Multi-lane infeed conveyor. Tray transport by pushing rods guided on both sides by motor-driven chains. Step by step movement with controlled speed to adapt to any type of tray, specific product, or production environment.

Electrical motion of bottom vacuum chamber combined with pneumatic sealing and cutting in the upper part for the most efficient and reliable packaging output with the lowest maintenance cost on the market.

Robust stainless steel frame and structure for high machine durability and ideal hygienic conditions. Overall rating IP 65.

ReePRO consumes very little compressed air saving you money in both power consumption and general maintenance; and thus, increasing return on investment.

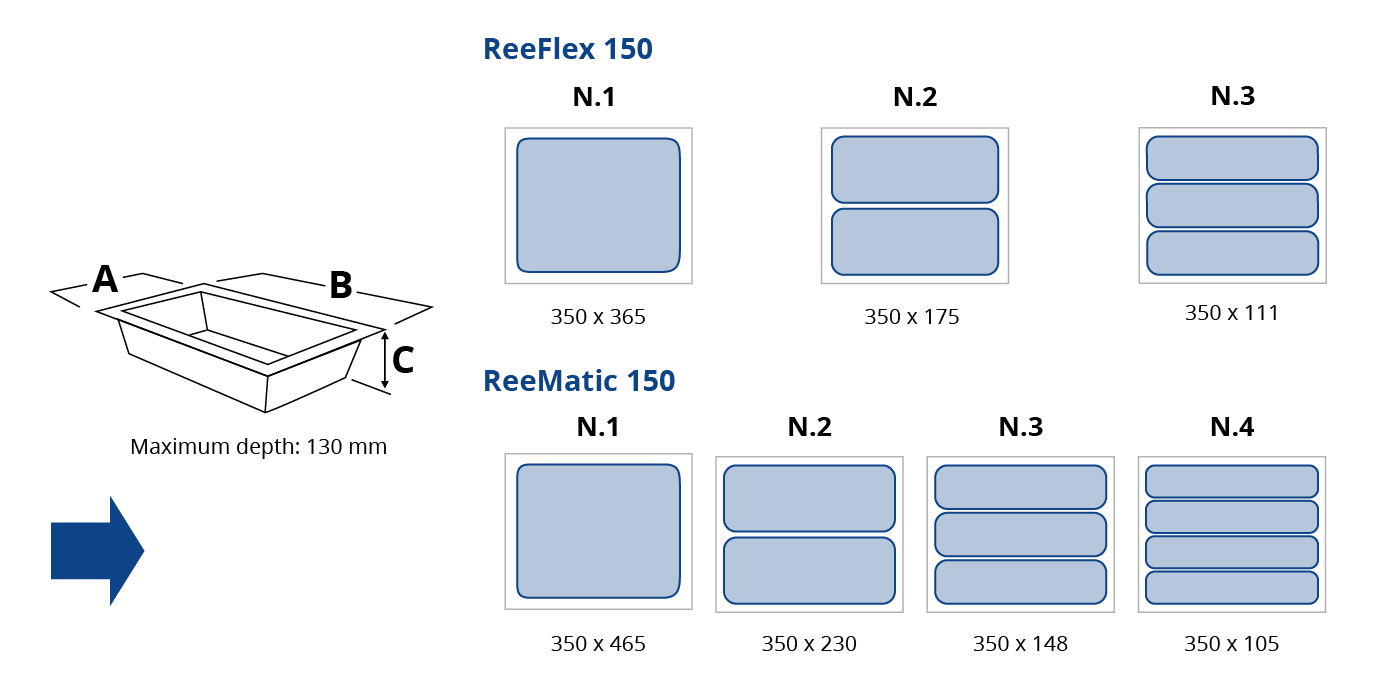

Reeflex & Reematic 150

Reliability, high performance and set-up flexibility. The ReeFlex or ReeMatic150 are fully automatic industrial machines designed for sealing pre-formed trays with full MAP system capabilities. They will process in parallel from 1-4 trays/cycle at speeds from 6-15 cycles per minute. These models store up to 15 different programs on Siemens PLC, and give a range of conveyor lengths choices and production line set-up options for further automation. Standard full stainless steel frames offer high protection against rust and ensures optimal hygienic conditions. Electro-mechanical lifting of the chamber reduces air consumption and provides energy savings and dependable movement.

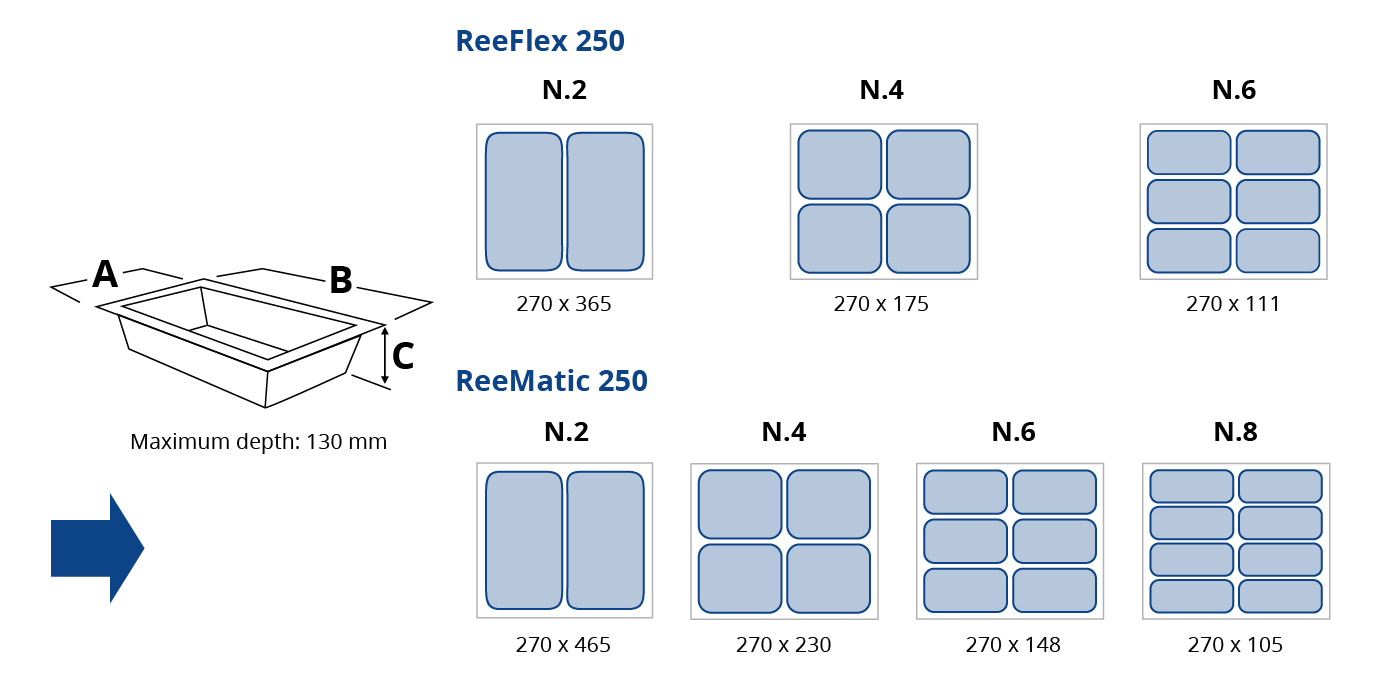

Reeflex & Reematic 250

Reliability, high-performance and set-up flexibility with increased capacity. The Reeflex or Reematic 250 are fully automatic double-chamber machines for sealing pre-formed trays with full MAP system capabilities and increased industrial out-put. They will process in parallel 2-8 trays/cycle at speeds from 6-15 cycles per minute. These models store up to 15 different programs on Siemens PLC, and give a range of conveyor length choices and production line set-up options for further automation. Standard full stainless steel frames offer high protection against rust and ensures optimal hygienic conditions. Electro-mechanical lifting of the chamber reduces air consumption and provides energy savings and dependable movement.