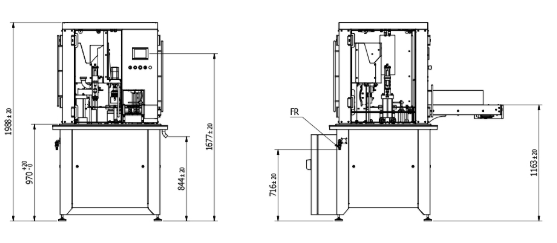

Fill Seal 2500

FS 2500

The Fill Seal 2500 model is a single-head filler/sealer with an eight-station rotary table. It guarantees a reliable and precise dosing and sealing cycle of up to 2,500 pieces per hour. This model is ideal for medium to large productions. Built in stainless steel it is suitable for any type of production environment.

The high versatility of this model allows packaging a wide range of liquid and doughy products such as yogurt, cheese, milk, margarine, butter, jam, honey, sauces, soups, etc., and also products containing some solid particles. The machine can run many types of container materials such as PP, PET, aluminum, cardboard, glass, and ceramic and can seal either precut lids or lidding films coming from a reel. Product change-over is quick and easy with minimum down-time.

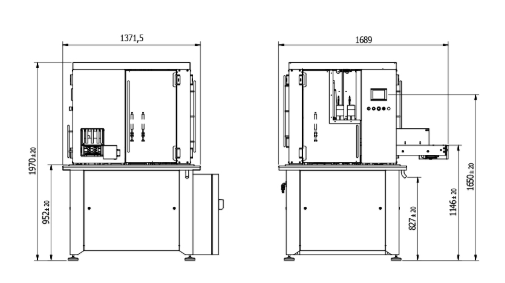

Fill Seall 5000

FS 5000

The Fill Seal 5000 model is a double-head filler/sealer with an eight-station rotary table. It guarantees a reliable and precise sealing cycle of up to 5,000 pieces per hour. This model is ideal for medium to large productions. Built in stainless steel it is suitable for any type of production environment.

The high versatility of this model allows packaging a wide range of liquid and doughy products such as yogurt, cheese, milk, margarine, butter, jam, honey, sauces, soups, etc., and also products containing some solid particles. The machine can run many kinds of container materials such as PP, PET, aluminum, cardboard, glass and ceramic and can seal either precut lids or lidding films coming from a reel. Product change-over is quick and easy with minimum of down-time.

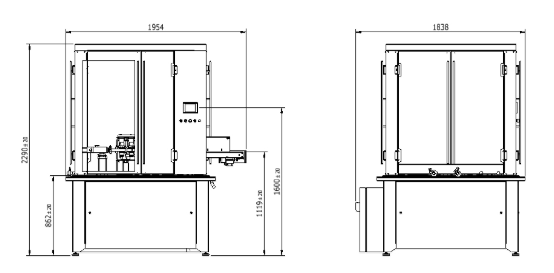

Fill Seal 7000

FS 7000

The FS 7000 Tronic model is a filling and closing machine equipped with automatic turntable, suitable for high productions up to 7,000 pots per hour. The machine can run 3 cups per cycle.

This innovative and compact high performance model can be opened on all sides to allow easy cleaning and servicing. The machine can be fully customised with the many options available. This model is entirely built in stainless steel and suitable for any type of production environment.

The high versatility of this model allows packaging a wide range of liquid and doughy products such as yogurt, cheese, milk, margarine, butter, jam, honey, sauces, soups, etc., and also products containing some solid particles. The machine can run several kinds of containers (such as PP, PET, APET, aluminum, cardboard, glass) and can seal either precut lids or lidding films coming from a reel.