Vacomat 1

This vacuum machine is a great innovation for domestic and semi-professional use. Its professional field origins make it incredibly performing. The Vacomat 1TT is equipped with different accessories that enable you to pack products not only in bags but also in rigid containers of different sizes. Vacuum-packed products keep their nutritional elements, aroma and color longer; their quality and economical value are guaranteed. The daily use of such machines in home kitchens is developing.

Vacomat 2

This vacuum machine is a great innovation for domestic and semi-professional use. Its professional field origins make it incredibly performing. The Vacomat 2TT is equipped with different accessories that enable you to pack products not only in bags but also in rigid containers of different sizes. Vacuum-packed products keep their nutritional elements, aroma and color longer; their quality and economical value are guaranteed. The daily use of such machines in home kitchens is developing.

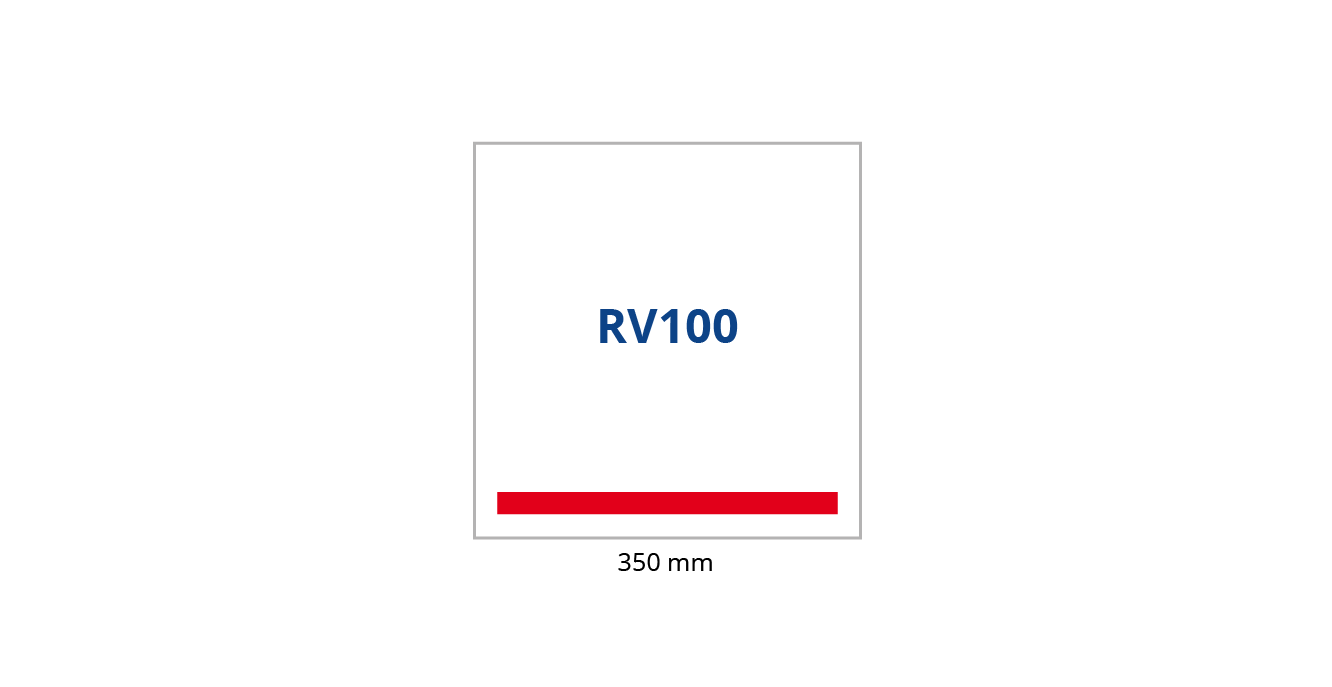

RV100

RV100 model is a small vacuum chamber packing machine for vacuum bags. The machine can be easily placed in any working area thanks to its compact external dimensions. This machine can be delivered with a mobile stand on wheels for easy relocation. A gas injection device (M.A.P.) can be included into the machine.

![]() Documentation

Documentation

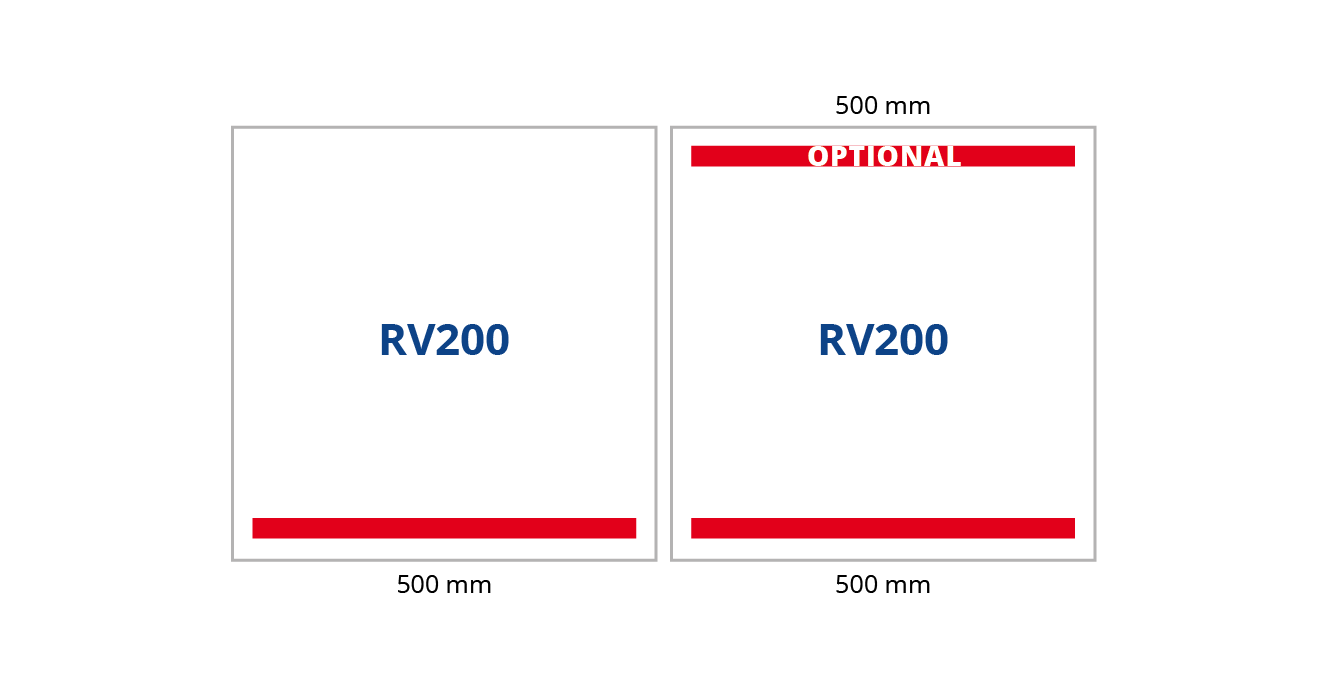

RV200

RV200 model is a medium size vacuum chamber packing machine. Featuring the largest chamber dimensions among tabletop machines, the RV200 is highly flexible with foodstuff dimensions. This model can be equipped with a mobile stand on wheels for easy movement and relocation. A gas injection device (M.A.P.) can be included into the machine.

RV300

Wheeled frame vacuum chamber machine. Equipped with a vacuum pump that allies a chamber size adaptable to many size products with a fast cycle for simple vacuum packing or for M.A.P. The smallest model in the RV range to reach high production out-puts.

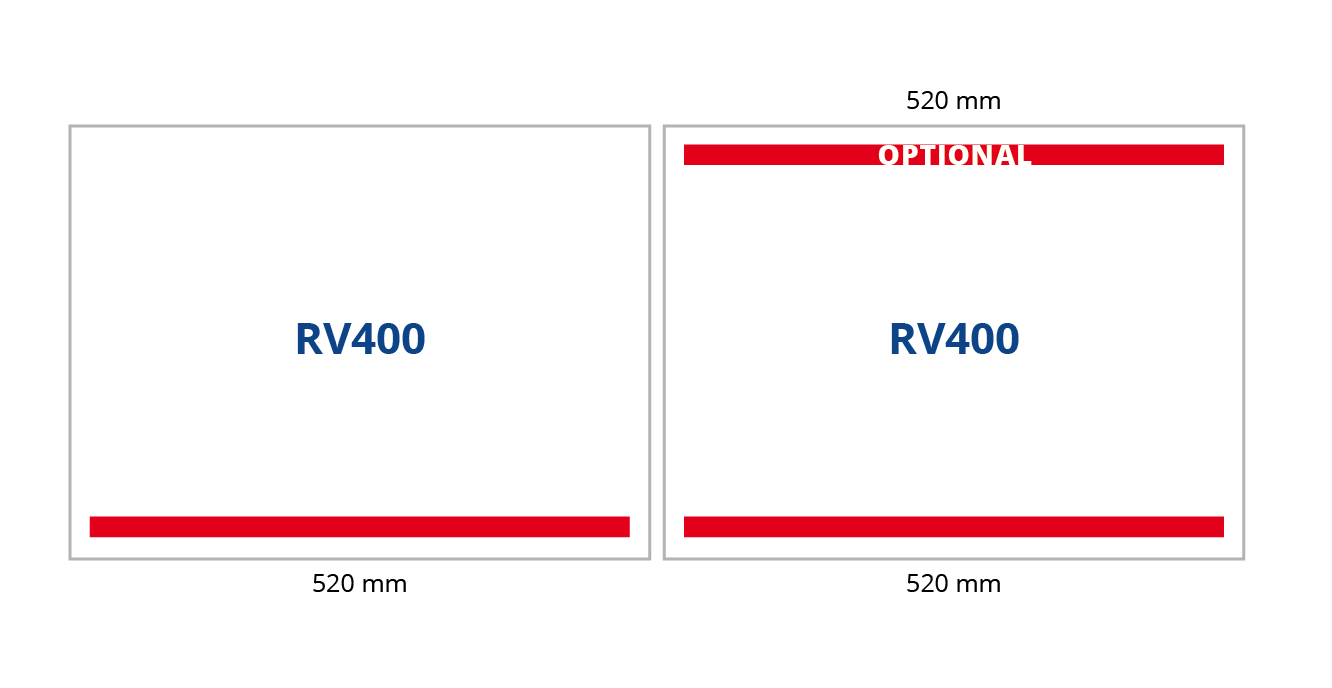

RV400

The large chamber dimensions of this model allows the packing of large product pieces in vacuum or M.A.P. The flexibility gained from multiple sealing bar positions make this machine efficient for industrial production, restaurant Kitchens or centralized catering uses.

RV 450 FL

Vacuum packaging machine designed for packaging difficult products with special lengths or widths requiring off-standard bags. This model is an excellent solution for packaging small or medium size bags whose flat covers allow reduced air volume evacuation, resulting in directly proportional increases in cycle speeds.

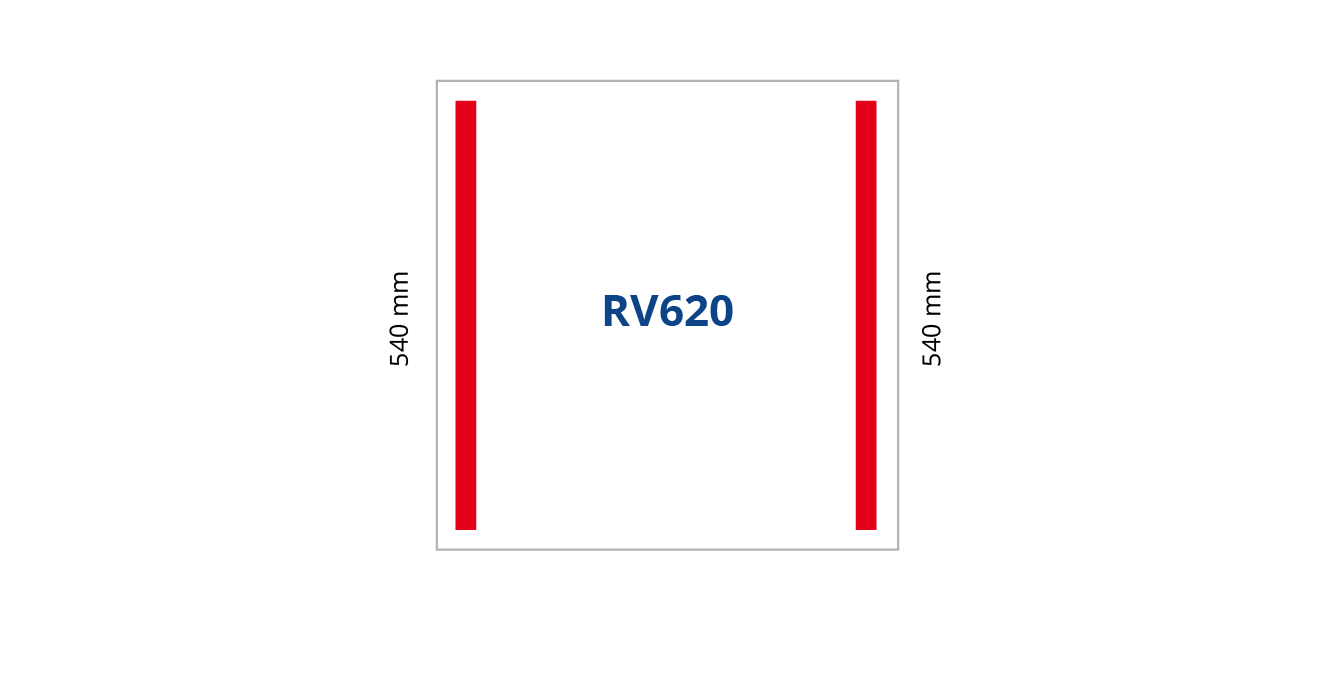

RV 620 RL

Vacuum packaging machine dedicated to the catering field. It allows packing of a Gastronom (1/2 steam) tray or, with 2 extensive sealing bars along both chamber sides, to maximize the number of packages that can be processed in a cycle. A maximum product height of 210 mm allows the packaging of products which are extremely bulky.

RV 630

Vacuum packaging machine for industrial use. Characterized by a large capacity vacuum chamber combined with a cover height of 210 mm. This machine is ideal for packing meat, cheese and food products with particularly difficult dimensions.

RV1000

Vacuum packaging machine designed for industrial use and large production. Characterized by a large capacity vacuum chamber combined with a total cover height of 370 mm in stainless steel. This machine ideal for packing bulky products in the shortest possible cycle times. A 300 m3/h vacuum pump powers this unit.

Flexible tailoring is possible with a number of options such as gas injection (MAP), bi-active sealing bars for multi-layer of high thickness pouches, Soft-Air system for pressure adjustments with delicate products, bag-excess trimming, automatic lid movements, extra lid height to 300mm, or roller conveyors.

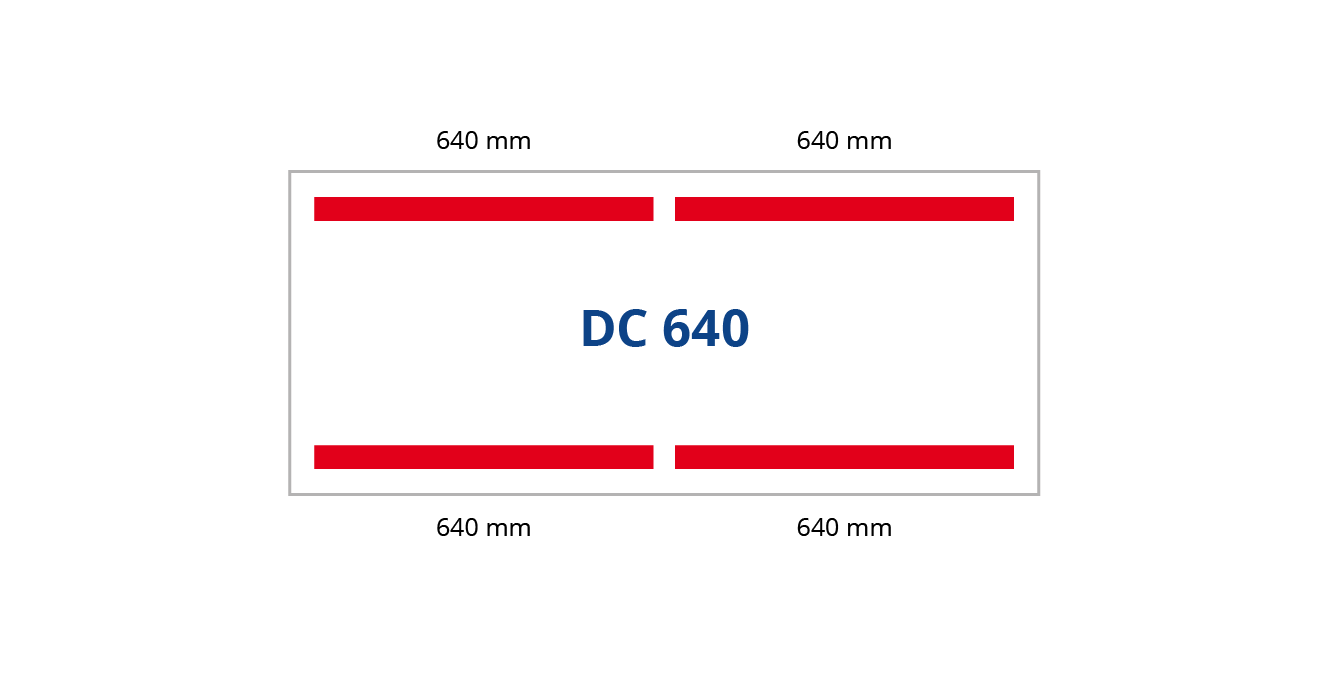

DC 640

Industrial double-chamber vacuum machine with swing-lid and flat-deck design. Chamber provides a useable product loading area of 640x560mm with two 640mm sealing bars allowing multiple small or medium bag positioning or single large size bulk products. Machine is equipped with either a100mc/h or 200mc/h pump with twister vacuum chamber system for high performance.

This model can be combined to a layout including a conveyor belt or automatic hot water dip tank for shrinkable bags.

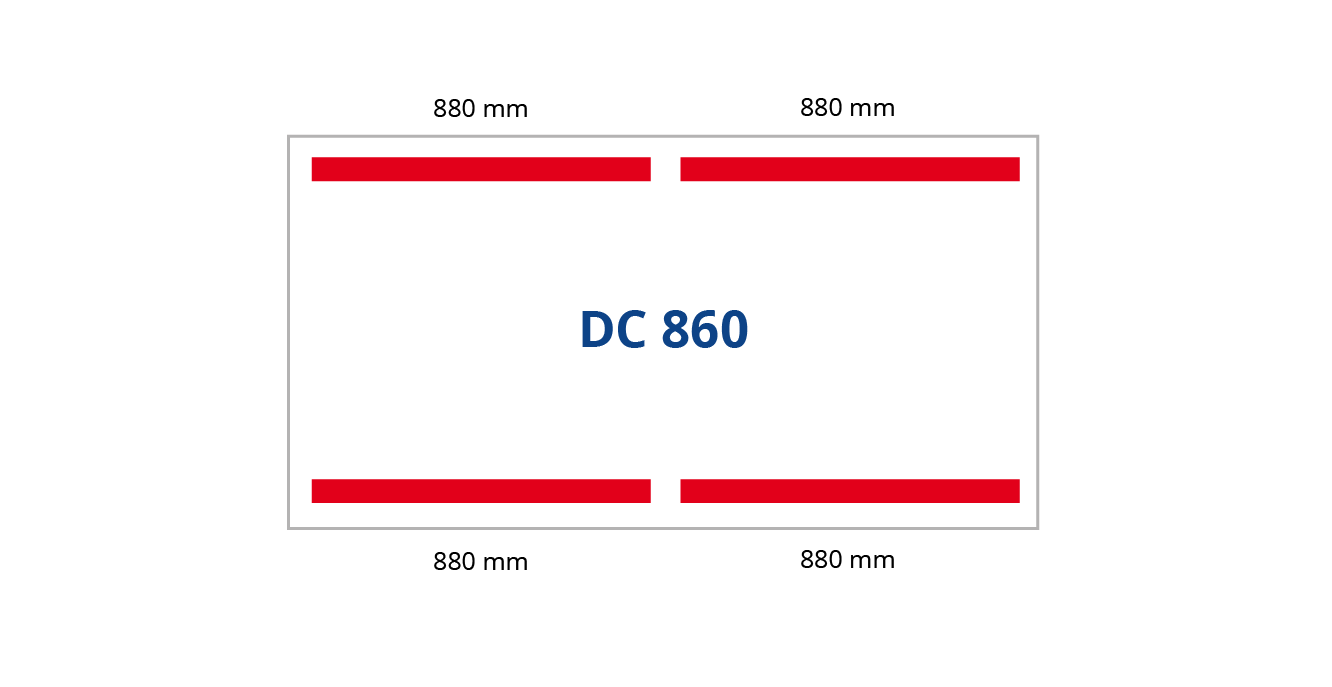

DC 860

Large industrial double-chamber vacuum machine with swing-lid and flat-deck design. Chamber provides a useable product loading area of 880x850mm with two 880mm sealing bars allowing multiple small or medium bag positioning or single large size bulk products. Machine is equipped with either a200mc/h or 300mc/h pump with twister vacuum chamber system for high performance.

This model can be combined to a layout including a conveyor belt or automatic hot water dip tank for shrinkable bags.

Fully manufactured in stainless steel Reepack’s BT series machines are highly flexible to different production needs. BT machines integrate easily with a hot-water dip-tank, drier, or flow-wrap unit.

Chamber configurations include single or double sealing bar formats, pump options range from 300m3/hr to 1000m3/hr. The BT series belt system vacuum chamber machines are offered in four different models.

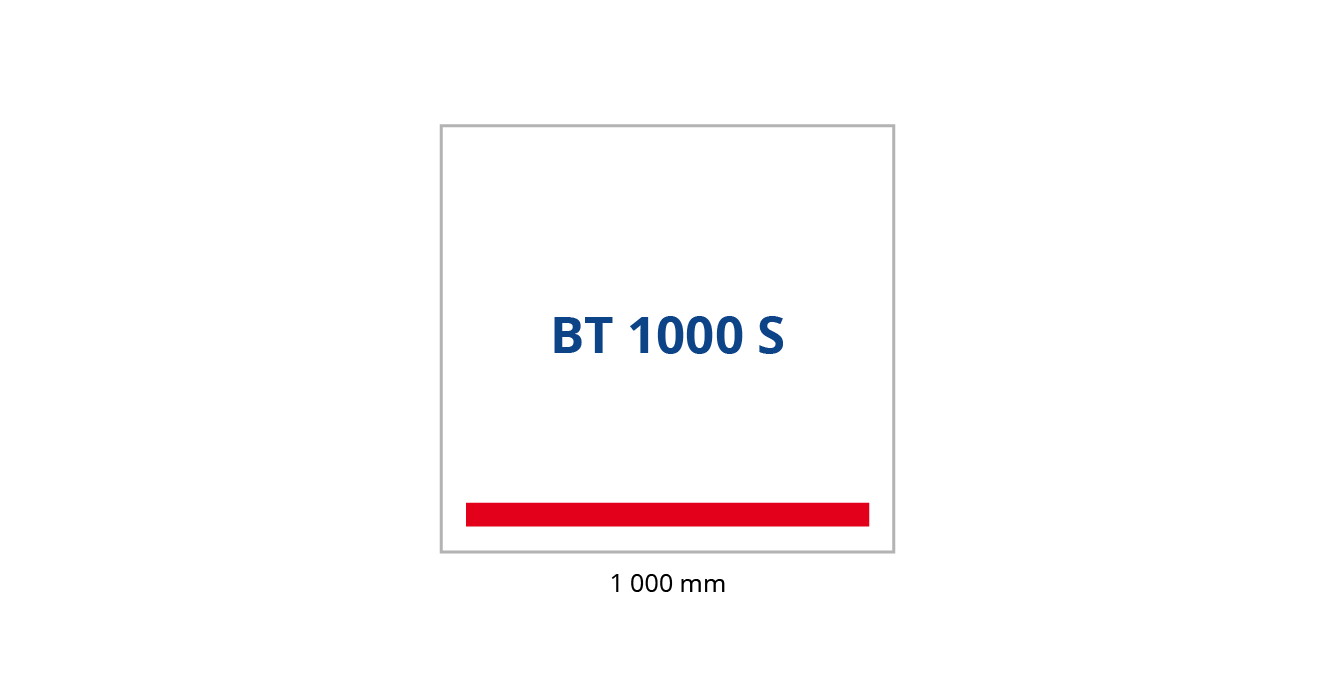

BT 1000 S

Automatic belt system vacuum chamber machine in full stainless steel build with adjustable belt speed. Chamber dimensions 1000x630x250mm with a single 1000mm Bi-Active sealing bar configuration in a frontal position. Control panel with PLC 15 programs recordable with digitial control of the vacuum and sealing temperature settings.

This model can be combined to a layout including a conveyor belt or automatic hot water dip tank for shrinkable bags

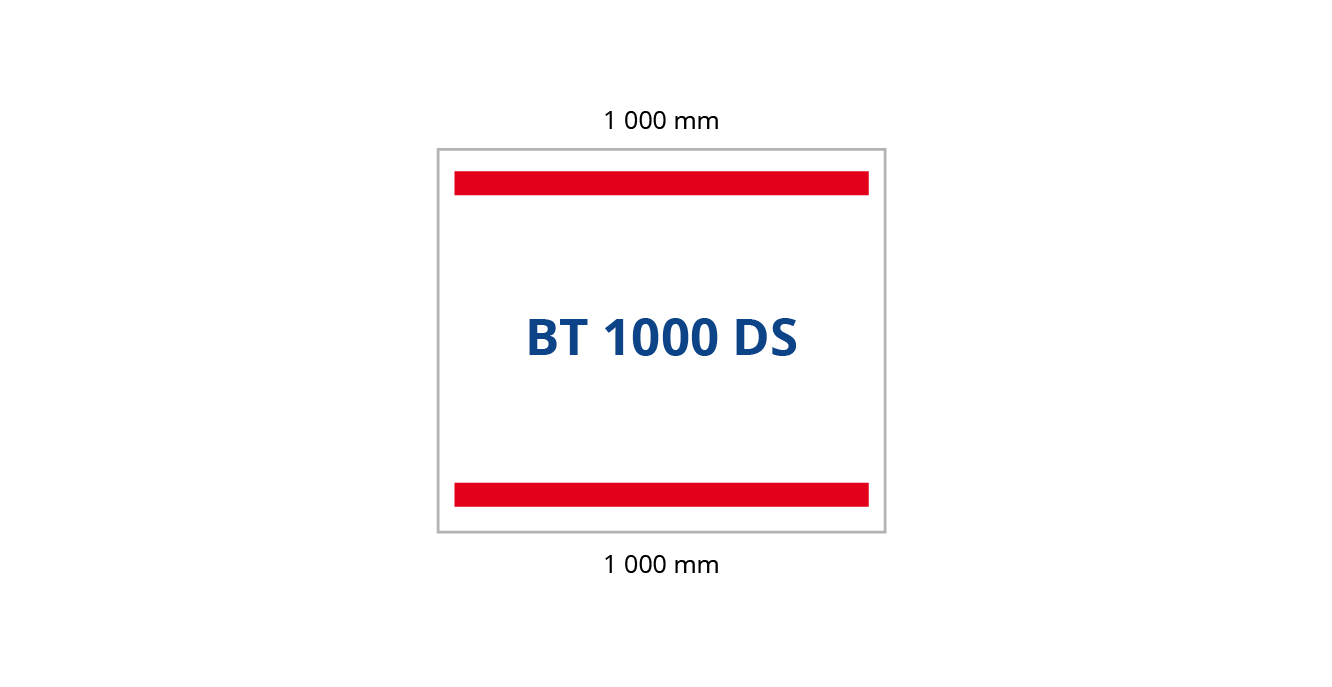

BT 1000 DS

Automatic belt system vacuum chamber machine in full stainless steel build with adjustable belt speed. Chamber dimensions 1000x570x250mm with double 1000mm Bi-Active sealing bars in parallel configuration frontal and back position. Control panel with PLC 15 programs recordable with digitial control of the vacuum and sealing temperature settings.

This model can be combined to a layout including a conveyor belt or automatic hot water dip tank for shrinkable bags.

BT 1000 DL

Wide automatic belt system vacuum chamber machine in full stainless steel build with adjustable belt speed. Chamber dimensions 1000x800x250mm with double 1000mm Bi-Active sealing bars in parallel configuration frontal and back position. Control panel with PLC 15 programs recordable with digitial control of the vacuum and sealing temperature settings.

This model can be combined to a layout including a conveyor belt or automatic hot water dip tank for shrinkable bags.

BT 1350 DL

The largest automatic belt system vacuum chamber machine in full stainless steel build with adjustable belt speed. Chamber dimensions 1350x800x250mm with double 1000mm Bi-Active sealing bars in parallel configuration frontal and back position. Control panel with PLC 15 programs recordable with digitial control of the vacuum and sealing temperature settings.

This model can be combined to a layout including a conveyor belt or automatic hot water dip tank for shrinkable bags.

ST-80E AUTOMATIC HOT WATER DIP TANK

Automatic 320 liter hot-water dip-tank for shrink bag. With electromechanical movement and PLC control this unit has automatic water level control and weekly clock settings for water heating.

Easily integrates with a vacuum chamber machine to form an automated line that can be completed with a draining outfeed conveyor or a drier.

DT-80 AUTOMATIC DRYER TUNNEL

Automatic drier tunnel with full stainless steel frame. This unit’s air circulation is assured by a high-pressure air compressor with upper and lower side blow mouths. It features automatic loading and unloading conveyor.

Easily integrates with a vacuum chamber machine and dip-tank to form a complete automated line.

BT Integrated Lines

Examples of typical BT automatic line layouts involving dip tank and drier tunnels or flow-wrap machines.

- BT 1000 Vacuum chamber to ST-80 automatic hot water dip tank.

- BT 1000 Vacuum chamber machine to ST-80 automatic hot water dip tank and DT-80 drier tunnel.

- BT1350 Vacuum chamber machine to Reeflow 50 flow-wrap machine.